Installation and replacement process of basin support

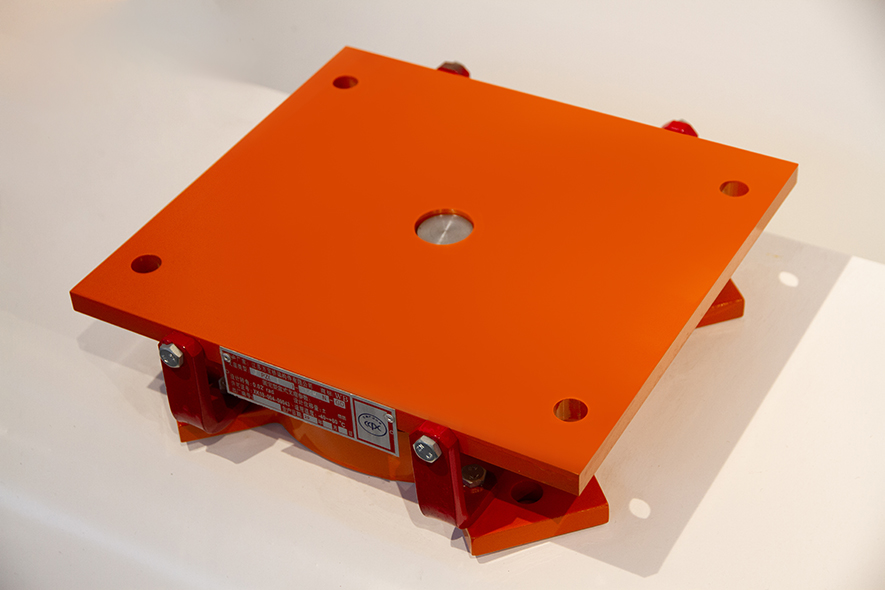

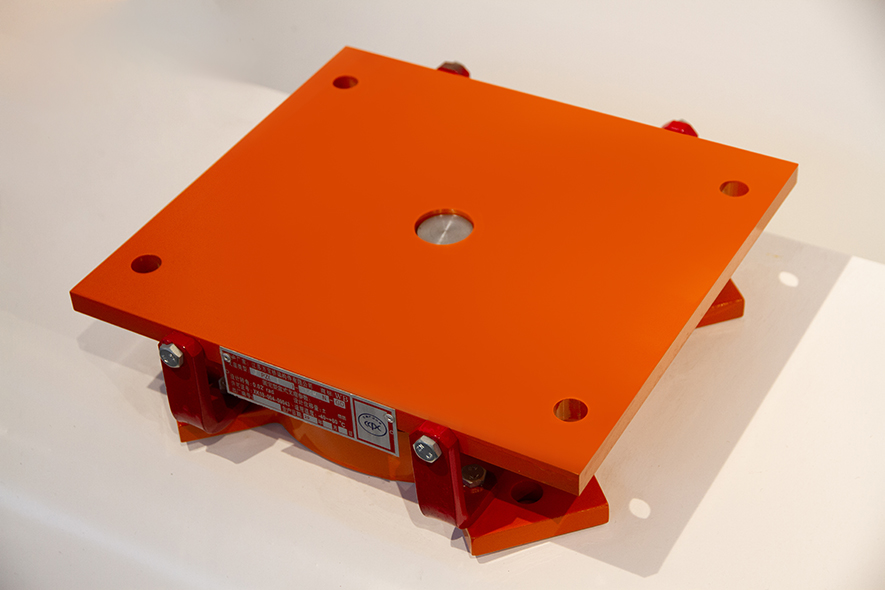

Whether it is an urban bridge or a highway bridge, continuous box girder is a commonly used structural form. In order to solve the vertical bearing capacity, horizontal displacement and rotation, the continuous box girder is currently commonly used basin-type rubber bearings. The installation and replacement of basin rubber bearings is an important part of bridge construction and maintenance, whic

Whether it is an urban bridge or a highway bridge, continuous box girder is a commonly used structural form. In order to solve the vertical bearing capacity, horizontal displacement and rotation, the continuous box girder is currently commonly used basin-type rubber bearings. The installation and replacement of basin rubber bearings is an important part of bridge construction and maintenance, which has attracted wide attention from the industry.

1. Determine the principled jacking plan based on the actual situation, that is, partial jacking or overall jacking. The advantage of local jacking is that it is easy to control the jacking and reduce equipment investment; the disadvantage is that jacking can easily lead to large deformation of the beam and a long construction period. The advantage of overall jacking is that it is easy to control the stress in the beam and the construction period is shorter, but more jacking equipment and personnel are required, and it is difficult to coordinate and control the deformation of various parts during the jacking process. If the design permits, try to give priority to partial jacking.

2. Calculate the theoretical jacking reaction force value of each part according to the beam structure form and design parameters, and determine the appropriate number and model of jacks according to the reaction force. The basic principles of "large size, moderate quantity, and controllable grading" should be followed when selecting models.

Large: It means to choose a jack model with a larger safety reserve factor as much as possible. For example, when choosing a jack, ensure that the actual jacking force is less than 75% of the theoretical jacking force.

Moderate quantity: It means that it is not advisable to use more jacks to achieve the requirement of total jacking force, and at the same time, it should not be too few, that is, there should be at least one jack on both sides of each support. More jacks will make it difficult to work together, and too few jacks will cause difficulty in starting or once an individual jack fails, it will affect the entire jacking process.

Hierarchical controllable: The jacking equipment with synchronous jacking information control system or the jack equipment with throttle control should be preferred to realize jacking synchronization or difference limit control.

3. It is necessary to choose the setting position of the jacking point reasonably to avoid local damage of the concrete. According to the design drawings, the top surface of the jack should be arranged within the beam, or the lifting surface should be adjusted to within the beam by means of beams or longitudinal beams. If conditions permit, the jack should be arranged near the support position on the cover beam. The force-bearing surface should adopt wedge iron, with a large force-bearing area, adjust the vertical and horizontal slope of the bottom of the box girder to ensure that the jack can apply force vertically.

4. When the space between the cover beam and the bottom of the beam cannot meet the jack layout requirements, a bearing column should be used as the back of the jack. When the pier column is not high, the bearing column should be placed on the cap, otherwise the foundation should be handled well to ensure that the strength and deformation of the foundation meet the lifting requirements. When the pier column is too high or the water pier should adopt the hoop method, the bearing column should be placed on the hoop corbel. The design of the bearing column should ensure sufficient strength and rigidity. The load-bearing column should preferentially adopt the steel pipe form.

5. In the jacking plan, the command and dispatch, information transmission, and feedback mechanism in the jacking process should be formulated in detail to ensure that the entire process is strictly controlled. Priority should be given to the use of walkie-talkies for synchronous information transmission, and the responsibilities and division of labor of management and operators at all levels should be clearly defined.

6. The jacking plan should clarify the emergency control measures for various risks, formulate several sets of emergency adjustment plans, implement them according to the favorable plan, and prepare according to the unfavorable plan to prevent serious quality accidents or safety accidents.

7. The lifting plan should clarify the control methods and measures for the synchronous displacement or the difference limit during the lifting process, and supplement it with real-time monitoring and measurement of displacement, stress, strain, etc. when necessary to ensure the safety of the existing beam.

8. The method of removing the old support and installing the new support shall be described in detail in the jacking plan. In particular, the installation process methods of the new bearing installation and the bridge construction are very different due to the constraints of different conditions in different periods. There may be local adjustments of the bearing installation method, which should be clarified in the plan.